pex solmon

pex solmon

Home to the best PCBs in the world

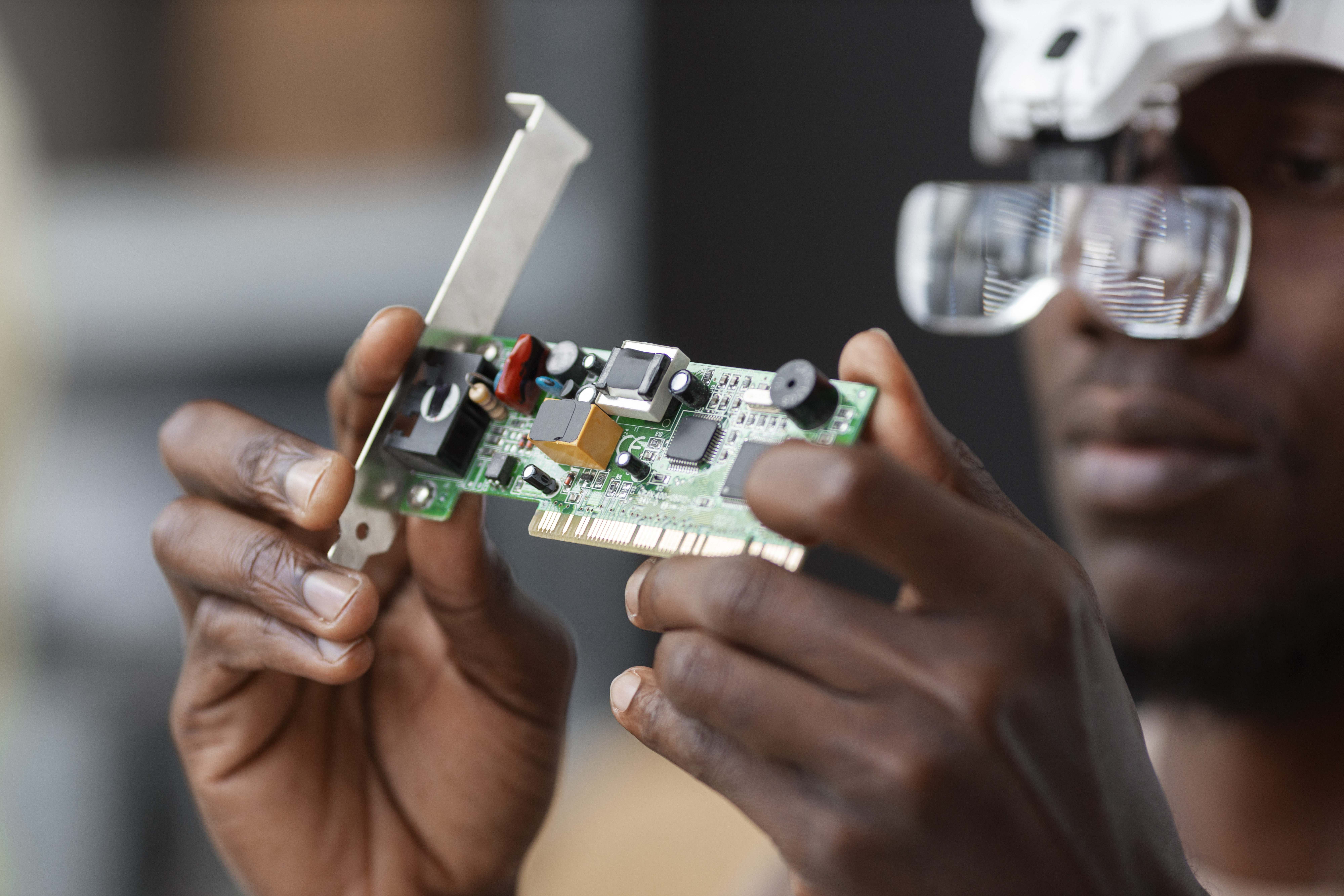

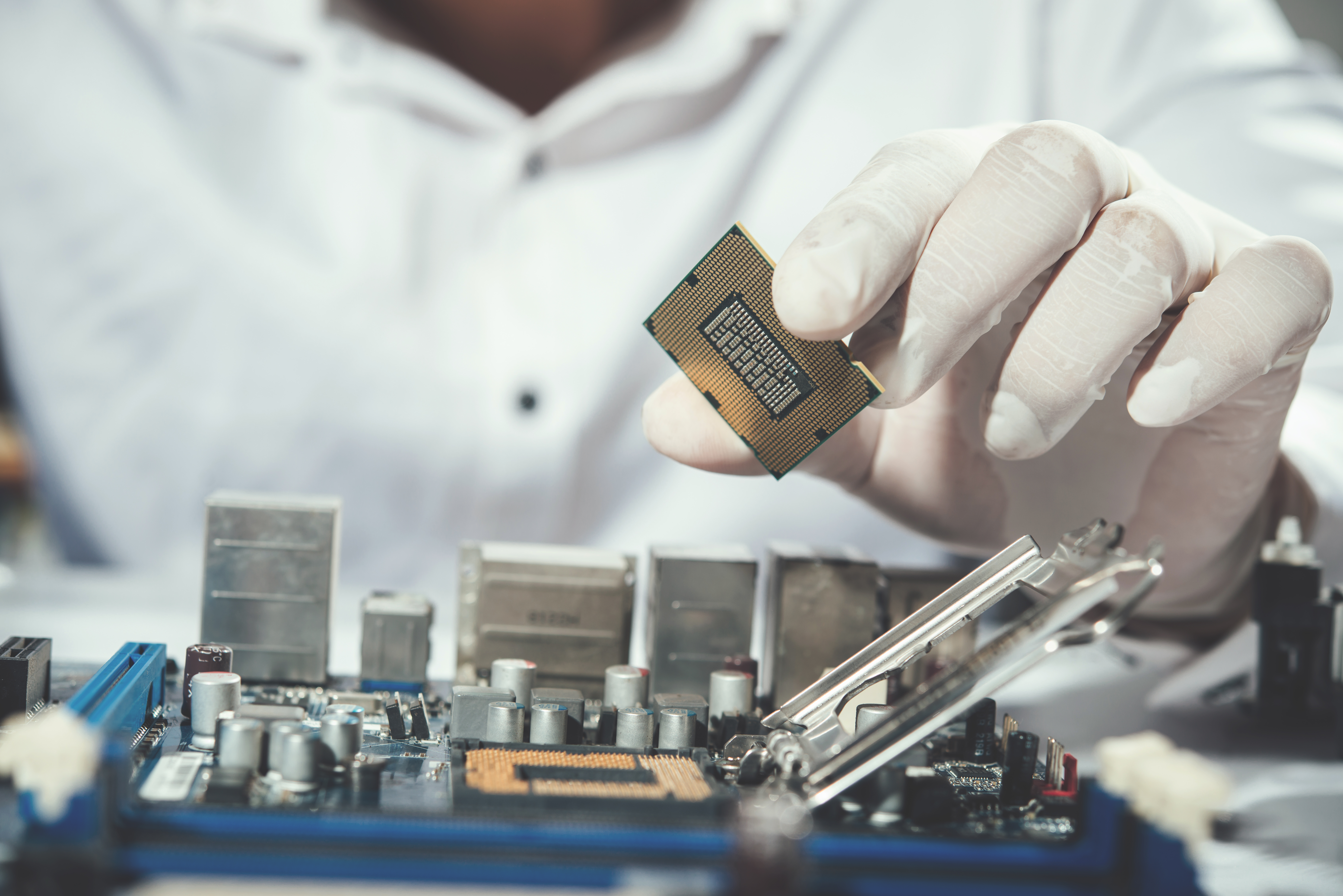

A printed circuit board (PCB) forms the backbone of an electronic product, providing the foundation to mount and interconnect components. Designing and manufacturing high-quality PCBs is a complex, multi-step process requiring expertise across electrical engineering, industrial processes, and quality control. This guide will walk through the end-to-end PCB production process spanning design, fabrication, assembly, and testing phases. Understanding the big picture helps streamline executing each step smoothly. We’ll cover key concepts like schematic capture, layout considerations, generating manufacturing files, selecting materials and finishes, assembly methods, and inspection processes. Let’s get started on a step-by-step journey following a PCB from initial concept through volume production!

Expanding the Limits of what's possible

More than PCBs

If you are looking for a custom manufacturer of PCBs to meet any requirement, you can't overlook Apex Solmon technologies. Our innovative PCB technologies are used in demanding applications in the automotive, aviation, industrial & medical, telecommunications, and computing sectors. Leading companies in their sectors throughout the world rely on our innovative force, decades of experience,

and excellent product and service quality for PCB and embedding solutions.

15 years of experience

600+ employees

3000 m² of production capacity per day

5 locations